FIRE PROTECTION CONSIDERATIONS

As stated in FM 1-53 there is no single protection appropriate for all anechoic chambers. Because of the range of chamber sizes, purposes, construction materials, and various chamber contents a specific protection goal should be established for each individual chamber. The need for adequate fire protection hinges on a couple of factors and needs to be coordinated carefully with both your local fire authority and your insurance carrier. Since each location is unique, local codes need to be thoroughly investigated to see what’s required in your municipality. Next, it’s crucial to check with your insurance underwriter to know exactly what they require; some might say a chamber is a stand-alone piece of equipment and doesn’t require any protection, but most will adamantly disagree saying it’s an occupied room and part of the parent building; therefore the chamber needs compatible fire protection. Other factors such as employee safety, existing fire systems, budgetary constraints, as well as maintenance costs after installation all weigh in when deciding on the level and type of protection needed. Regardless pre-approval is required by the jurisdiction having local authority.

Another detail to carefully review is whether the testing being performed in the chamber utilizes high power, and are the products being tested heat producing? If the answer is yes, this becomes a pivotal factor in determining the level of protection required. The greater the risk of fire or catastrophic consequences should a fire break out, the higher the level of protection needed in the chamber.

FM Global 1-53 data sheet provides good loss prevention and control recommendations for fire and associated perils in anechoic chambers. After the chamber fire system’s detection and suppression are designed, the drawings should be stamped by a fire protection engineer registered in the State of installation. At a minimum the systems must meet Factory Mutual 1-53 Property Loss Prevention, NFPA Standards and any other codes or standards having jurisdiction. The FM 1-53 standard is a very stringent standard and requires a considerable volume of water and pressure. A water flow and pressure test should be performed to determine if the water volume and pressure are adequate. The system may require a booster pump to bring the pressure up to necessary level. An alternative is to use the NFPÅ-13 standard for ordinary hazard. Fire Protection design is also based on guidelines by FM 1-53.S1, 1-53.S2, and NFPA 13 (1999) ED., and NFPA71.

There are two forms of fire protection that are predominantly used in anechoic chambers. The most common is the sprinkler system but it’s also the most risky in terms of accidental damage. Water is an enemy of RF shielding and absorber material. Another form of fire protection is the clean agent system with the most common being FM-200. It’s often used when high dollar systems are being tested and/or where water damage is deemed more costly than a fire. For this reason we see FM-200 as the best fire protection for anechoic chambers and RF shield enclosures.

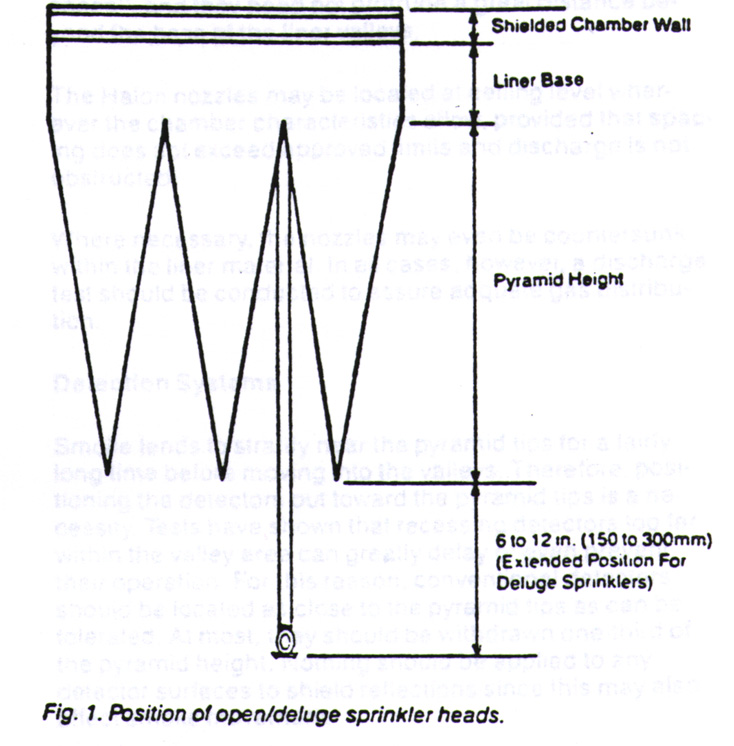

SPRINKLER SYSTEM (Water): uses either fixed heads or telescoping sprinkler heads. The fixed sprinkler heads are extended beyond the absorber tips using Blazemaster CPVC pipe. This can be either a wet pipe system or a pre-action water extinguishing system. Telescoping heads require the pre-action water system. Wet pipe systems are more commonplace and generally less expensive; however, should the wet system be activated the cleanup and costs to refurbish the chamber are usually

SPRINKLER SYSTEM (Water): uses either fixed heads or telescoping sprinkler heads. The fixed sprinkler heads are extended beyond the absorber tips using Blazemaster CPVC pipe. This can be either a wet pipe system or a pre-action water extinguishing system. Telescoping heads require the pre-action water system. Wet pipe systems are more commonplace and generally less expensive; however, should the wet system be activated the cleanup and costs to refurbish the chamber are usually enormous. When a sprinkler system is required it is recommended that a dry pipe system be used, which is triggered by the use of a smoke detection system. This minimizes the risk of accidental discharge and damage to the equipment in the chamber, the absorber and shielding as well.

enormous. When a sprinkler system is required it is recommended that a dry pipe system be used, which is triggered by the use of a smoke detection system. This minimizes the risk of accidental discharge and damage to the equipment in the chamber, the absorber and shielding as well.

CLEAN AGENT SYSTEMS: are the other option; they are more costly but won’t destroy the RF shielding, absorber or test equipment in the chamber. FM-200 has now replaced Halon and the agent being used is environment-friendly. Clean agent systems may require a backup system, (a reserve tank or water) depending on your local codes and ordinances. Automatic door and damper closers are required to seal the chamber before activation. Should the clean agent be discharged the cost to reload the system can be considerable depending upon the size of the chamber.

DETECTION & ALARM: A Complete Early Warning Fire and Detection system can be provided and installed in your anechoic chamber. For example; an early smoke detection system such as the “Vesda Laserplus System” consisting of a detection unit, display module, programmer and sampling network works very well. Should a false alarm occur, there is time to cancel/disable the release of Water or FM-200 preventing an accidental discharge.